Wait...Specialized doesn't make pedals you say. These are a pair of old Specialized pedals from the 80's. I believe they are MKS with a Specialized stamped on the back side, so technically you might be right.

The first thing you want to do is get all the tools you are going to need. A magnetic bowl to put your parts in is real handy, a 6mm allen wrench to hold the axle from the backside, a 12mm wrench to untighten the lock-nut, and a pedal cap wrench.You can get the job done with channel locks or pliers as last resort, but the pedal cap wrench get the cap off without marring the cap in any way.

Now that the cap has been removed, now you can loosening the lock nut. It might surprise you, but both the right pedal and left pedal are right hand thread for the bearing adjustment. Since the threads that thread into the pedal on the left side are left hand thread and follow the law of precession.

Now that the cap has been removed, now you can loosening the lock nut. It might surprise you, but both the right pedal and left pedal are right hand thread for the bearing adjustment. Since the threads that thread into the pedal on the left side are left hand thread and follow the law of precession. All bearing cone, washer, and locknut are in the bowl for inspection. Looks like we have contaminated bearings. Note: 11 bearing per side.

The cup, bearings, and cone under the cap side are as good as you would expect.

The backside not so much

In a case of rust it good to have some scotch brite, Ultra fine Scotch brite, and ultra fine steel wool.

After a once over...

...upon closer inspection the spindle's bearing surface is pitted. It's never going to be perfect again. You can only do the best with what you have left.

I started with medium grit emery paper, then fine, 400, 600, grit wet sand paper back by a small file

Chuck the axle in you drill and polish with some ultra fine scotch brite.

It's far from perfect, but it was a lot better than what you had. Even if you spent the time sanding out all pits, odds are you would deform and enlarge the shape of the bearing surface. Now if you have a lathe or mill, we might have a solution.

Now it's time to work on the cup. Dremel makes a nice small, fine, stainless wire brush that removes a lot of the muck.

Dremel also has 3 different grits of polishers that come in real handy for things like this.

Like I said, It's not perfect, but it makes the best of what you have. I've heard of people using JB-Weld to fill the pits. suspect it would work great for a while, but over time after the grease gets ground into the JB-Weld I suspect it will dislodge and possible lock up your bearings.

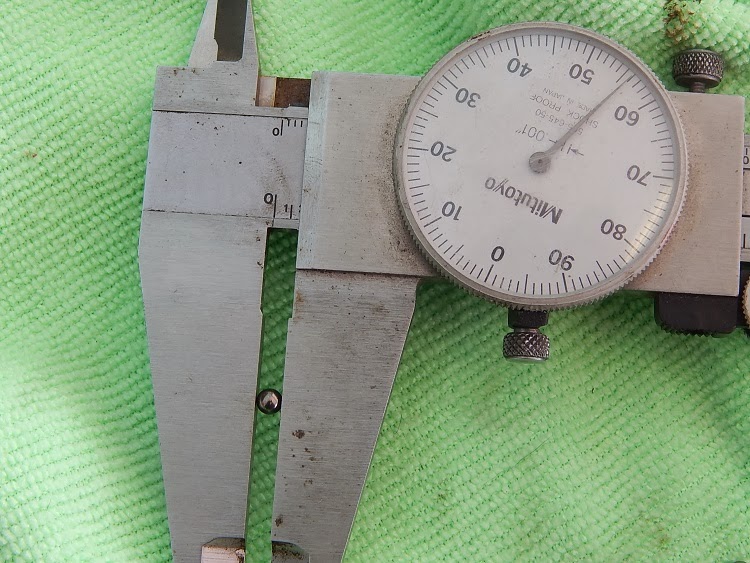

Toss all the old bearings, even the best ones. Just to double check 0.156" or 5/32"

Now pack with a quality grease like Phil Wood .

Now after it's been reassembled and adjusted I'd put the smoothness factor at a little below a Shimano 105 so to speak. Remarkably there were no tight and loose spots, and the bearing feel is real consistent. I've felt new pedals that didn't run as smooth, so take away from that what you can.

No comments:

Post a Comment